Smedesegment foar Shantui Komatsu CAT

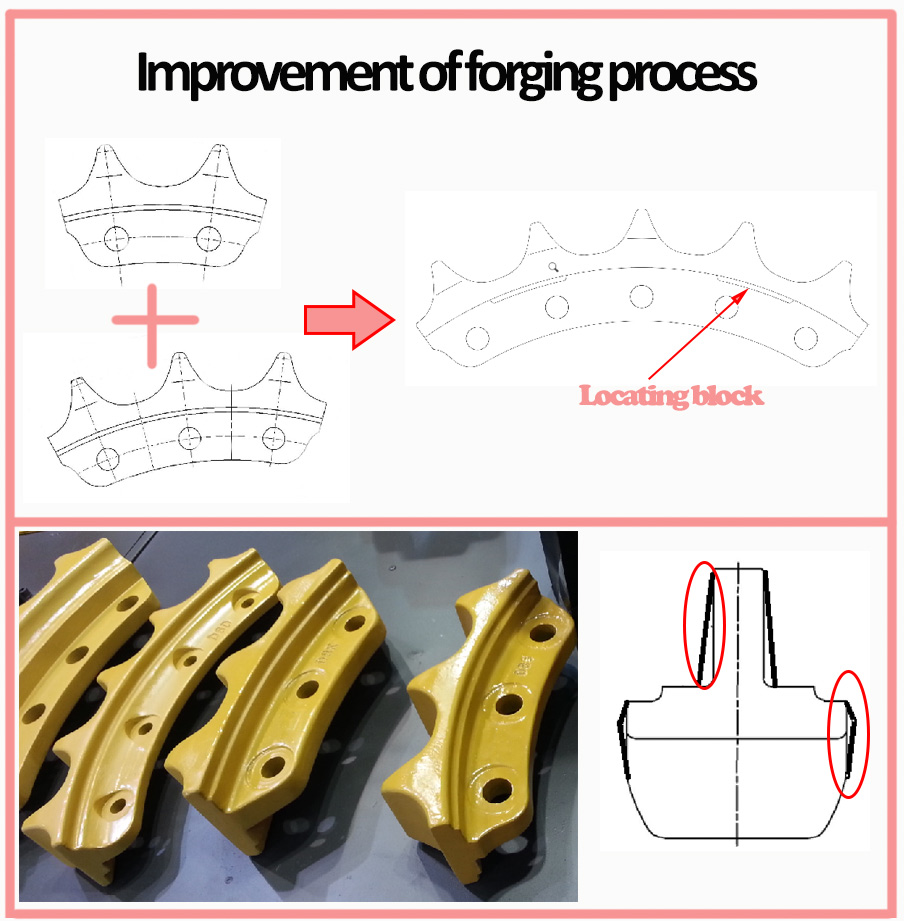

Ferbettering fan it smeedproses

It feroarjen fan twa of trije tosken nei fiif tosken ferminderet it foarkommen fan loslitten fan toskblokken. It feroarjen fan de posysjonearringssirkel nei in posysjonearringsblok ferminderet ferwurkingsfouten en ynterferinsje tusken de posysjonearringssirkel en it ynstallaasje-oerflak feroarsake troch deformaasje fan waarmtebehanneling.

Troch it smeedproses binne de syd- en flensflakken fan 'esegmint yn it oprjochte smeedproses moatte in bepaalde ûntwerphoeke behâlde wurde, en it masjinearre oerflak fan it smeide healfabrikaat produkt moat ferwurke wurde.

Model dat wy kinne leverje

| SEGMENT | ||||||||

| Model | OEM | Toanhichte | Tosk | Hols | Iepenbiering (mm) | Gewicht | Merk | Oare OEM (BERCO) |

| DH08 | 111H-18-00001 | 154 | 3 | 3 | 17.5 | 4.1 | shantui | |

| 111H-18-00002 | 4 | 4 | 17.5 | 5.5 | shantui | |||

| SD13 | 10J-18-00043 | 190 | 5 | 5 | 19.3 | 10.75 | shantui | |

| DH36 | 1175-18-00009 | 228.6 | 6 | 6 | 26.5 | shantui | ||

| 1175-18-00035 | 5 | 5 | 26.5 | |||||

| SD16, D65, D60, D85ESS-2 | 16Y-18-00014H | 203.2 | 3 | 3 | 23.5 | 8.5 | shantui/komatsu | 14X-27-15112/1,141-27-32410,144-27-51150,615-4149,KM2111,KM162 |

| (16J-18-00049) | ||||||||

| SD22, D85 | 154-27-12273A | 216 | 5 | 5 | 23.5 | 15 | shantui/komatsu | 155-27-00151,615-4150,KM224 |

| SD32, D155 | 175-27-22325A | 228.6 | 3 | 3 | 26.5 | 12 | shantui/komatsu | 175-27-22325/4 17A-27-11630,KM193,17A-27-41630 |

| SD52, D375 | 185-18-00001 | 280 | 5 | 5 | 28.5 | 33 | shantui/komatsu | 195-27-33110/1, KM1285 |

| SD90, D475 | 1189-18-00001/ | 317.5 | 5 | 5 | 31.5 | 43 | shantui/komatsu | |

| 198-27-42260 | ||||||||

| D50, D41, D58, D53 | 131-27-61710 | 175 | 3 | 3 | 19.5 | 6 | komatsu | 131-27-61710, 131-27-42220, KM788 |

| D5B | 5S0836 | 175 | 3 | 3 | 18 | 5 | KAT | 6Y5244, CR4408.7P2636 |

| D6D/C/G | 6T4179/6T4179/6P9102 | 202.8 | 5 | 4 | 17.8/20.8 | 11.57 | KAT | 6Y5012,5S0050,7P2706,CR3330,CR3329,8P5837,8E4365/CR5476,117-1616 |

| D6H/R | 6Y2931/1026677 | 202.8 | 5 | 5 | 17.8 | 11.5 | KAT | 7G7212,8E9041,7T1697,CR5515,173-0946 |

| D7G/E/F | 8E4675/8E4675/8E4675 | 216 | 5 | 4 | 20.8 | 14.7 | KAT | 5S0052, 3P1039, 8P8174, CR3148 |

| D8N/R.D7H/R | 7T9773/6Y2354, | 215.9 | 5 | 7 | 20.8 | 16.4 | KAT | 6Y3928,CR5050,9W0074 |

| 6Y2354/7T9773 | ||||||||

| D8N/R.D7H/R | 314-5462 | 215.9 | 5 | 5 | 20.8 | 16.4 | KAT | CR7160 |

| D8K.D8H | 6T6782/6T6782 | 228.6 | 3 | 3 | 24.5 | 12 | KAT | 2P9510,5S0054,CR3144 |

| D6N.D6M | 6I8077/6I8077 | 190 | 5 | 5 | 18.5 | 9 | KAT | 6I8077/8,CR5875 |

| D9N | 7T1247 | 240 | 5 | 6 | 24.6 | 23.98 | KAT | CR4686 |

| D10N | 6T9537 | 260.35 | 5 | 6 | 27.61 | 26.7 | KAT | CR5047 |

| 832 | 632-7793 | 228.6 | 3 | 5 | 26.5 | 11.63 | KAT | |

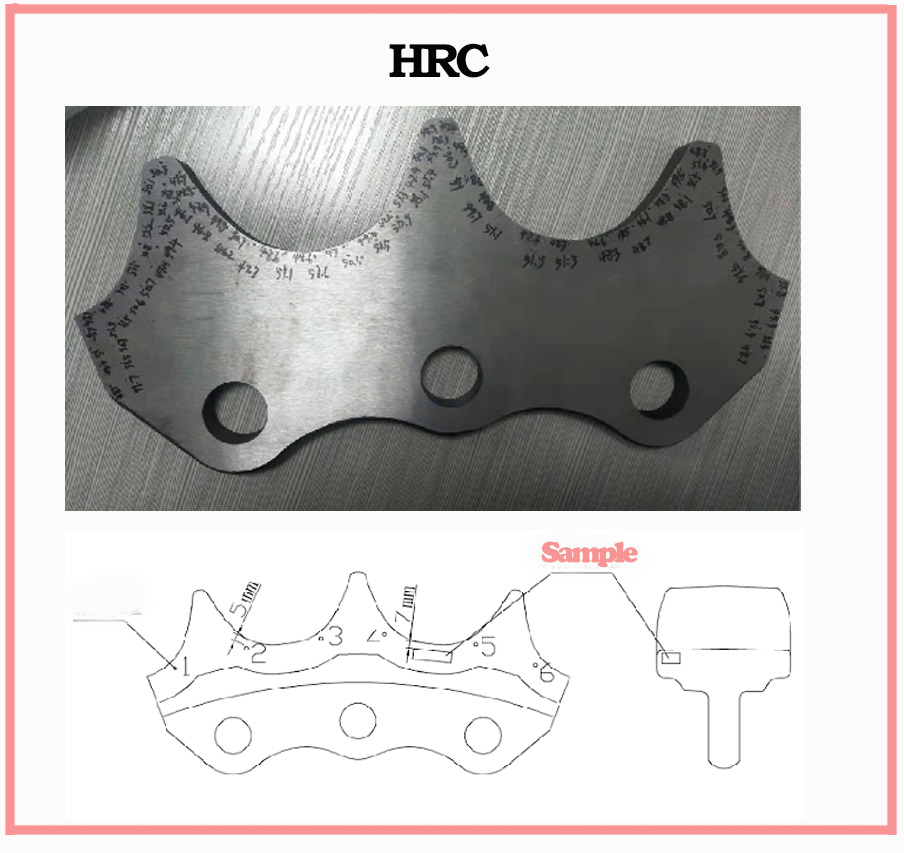

HRC

Fanwegen it smeidproses moatte de syd- en flensflakken fan it segmint yn it oprjochte smeidproses in bepaalde ûntwerphoeke behâlde, en it masjineare oerflak fan it smeide healfabrikaat produkt moat ferwurke wurde.

Ynpakken